真空低温脱水设备简介

食品的真空低温脱水,由于真空的存在(≤-0.099Mpa),使得脱水占相当重要的地位,因此在意义上与常温油炸有所不同。真空低温脱水是在70年代初兴起的,由于所得产品比一般传统油炸工艺具有更好的品质,90年代以后,该技术的发展更快,应用范围更广。这种食品较好地保留了其原料的原有风味和营养成分,味道可口,品种广泛,产品附加值高,因此具有广阔的开发前景。

真空低温脱水的基本原理是利用在减压的条件下,食品中水分汽化温度降低,能在短时间内迅速脱水,实现在低温条件下对食品的脱水。热油脂作为食品脱水的供热介质,还能起到改善食品风味的重要作用。其中,果蔬脆片产品被称为“二十一世纪食品”。

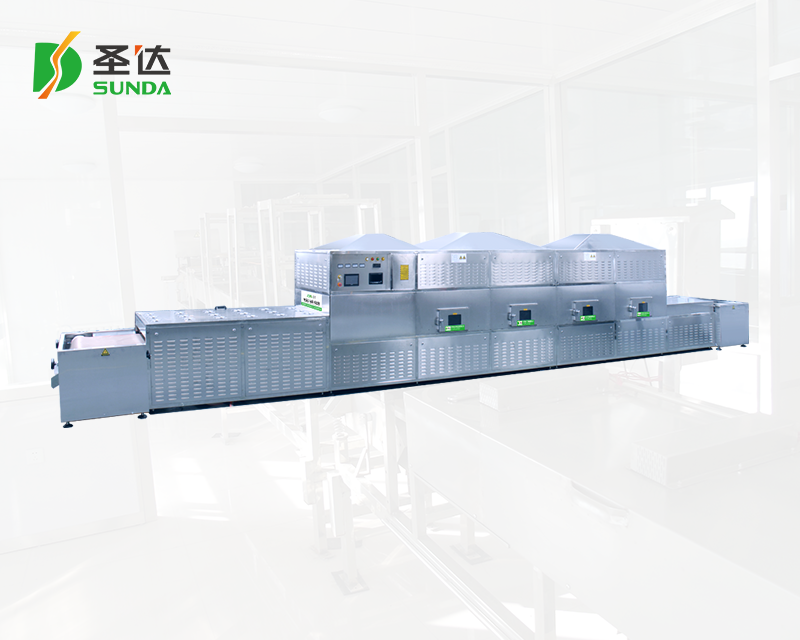

真空低温脱水设备真空泵机组是果蔬脆片加工的核心设备,具有操作维护简便,可靠性及加工效率高等显著特点,加工出的产品,可达到较高品质要求。

Equipment introduction

Due to the existence of vacuum (≤ - 0.099mpa), dehydration plays an important role in low-temperature vacuum dehydration of food, so it is different from room temperature frying in meaning. Vacuum low-temperature dehydration was developed in the early 1990s. Since the product obtained has better quality than the traditional frying process, the technology has been developed faster and applied more widely since the 1990s. This kind of food retains the original flavor and nutritional components of its raw materials. It has a wide range of varieties and high added value, so it has a broad development prospect.

The basic principle of vacuum and low temperature dehydration is to use the condition of vacuum and low temperature to reduce the vaporization temperature of food, which can dehydrate quickly in a short time, and realize the dehydration of food under low temperature. As the heating medium of food dehydration, hot oil can also play an important role in improving food flavor. Among them, fruit and vegetable chips are known as "21st century food".

The vacuum pump unit of vacuum low temperature dehydration equipment is the core equipment of fruit and vegetable chips processing. It has the remarkable characteristics of simple operation and maintenance, high reliability and processing efficiency, energy saving and so on. The processed products can meet the higher quality requirements.